How does screen printing work?

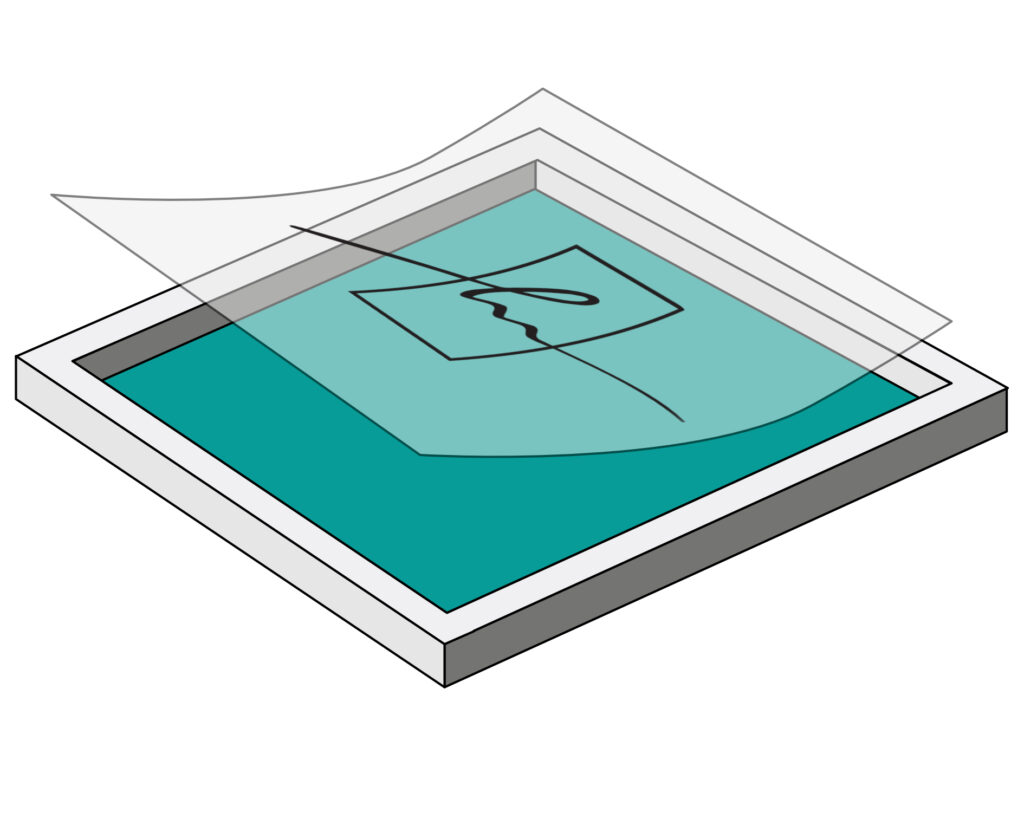

1.

The screen printing film, a transparent film, is prepared. The desired print motif is black on this, while unprinted areas remain transparent.

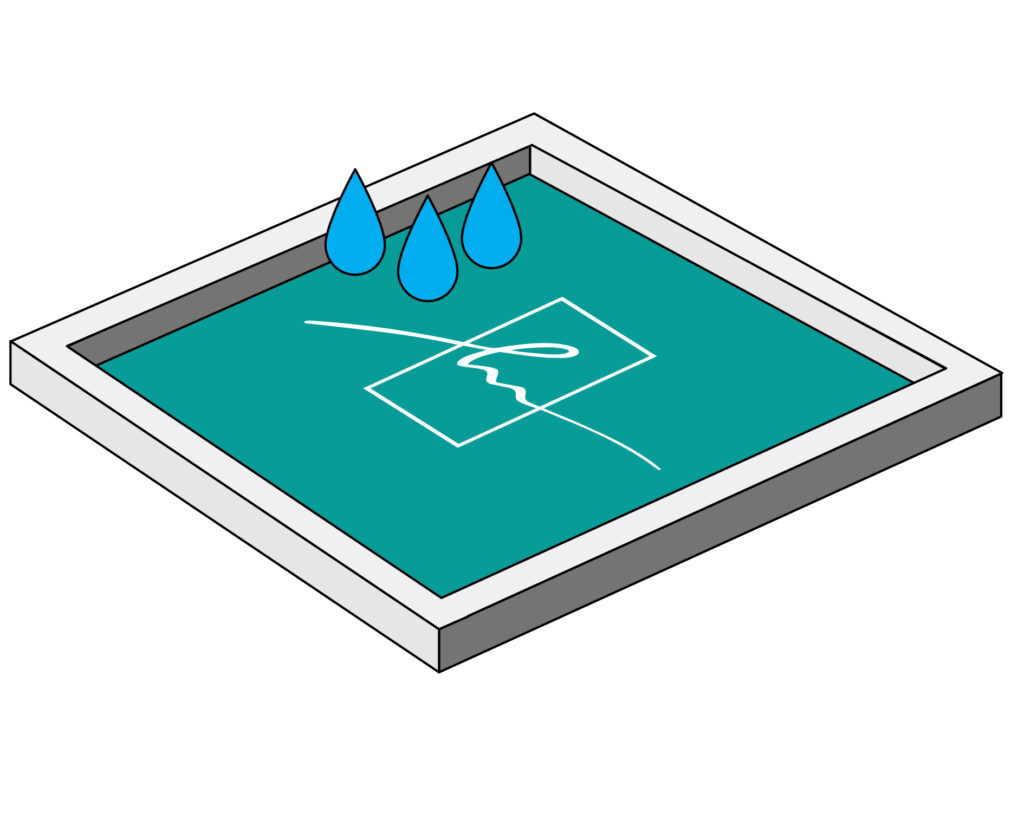

2.

After irradiation with UV light (exposure), the uncured layer under the black colour is washed out with water and is now translucent.

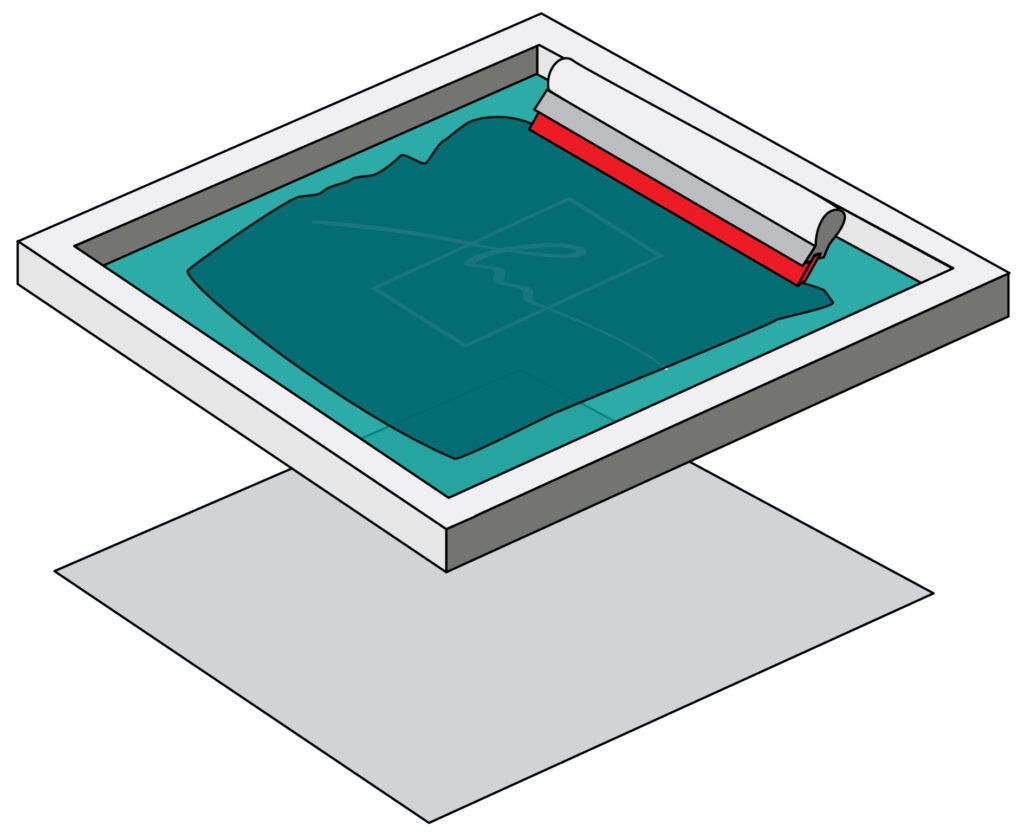

3.

The print motif is fully covered with colour or varnish (flooding).

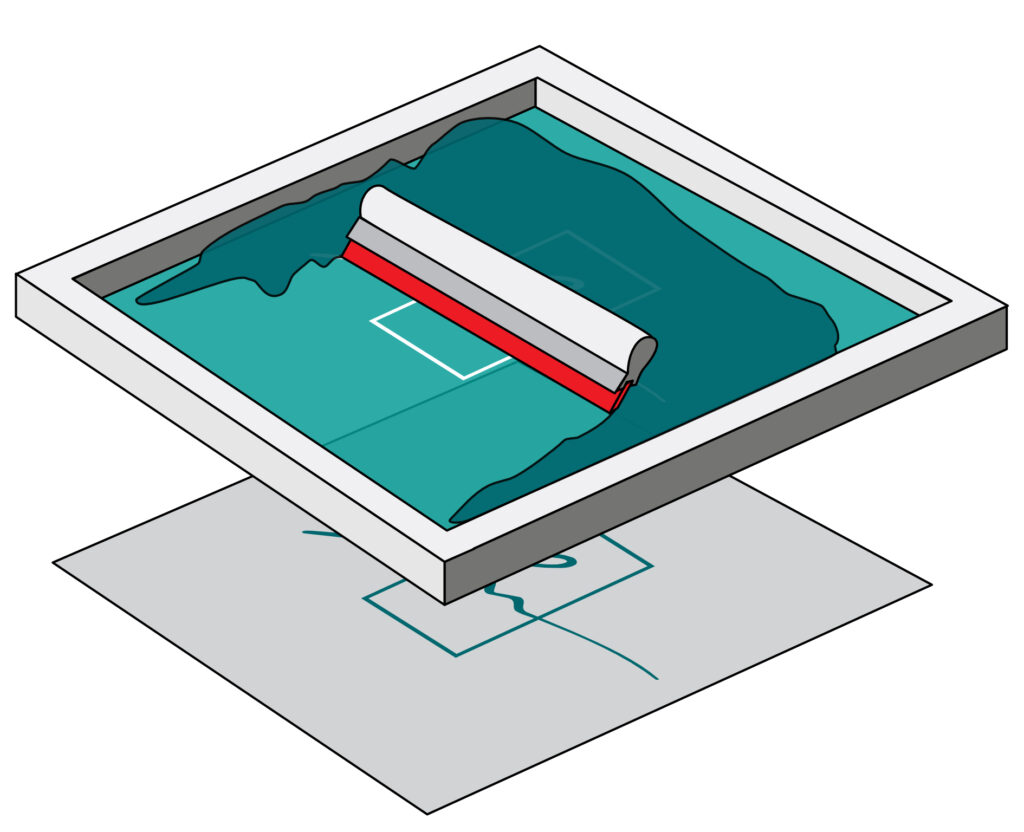

4.

The screen printing squeegee is used to press the ink through the screen onto the substrate.

Special features of screen printing

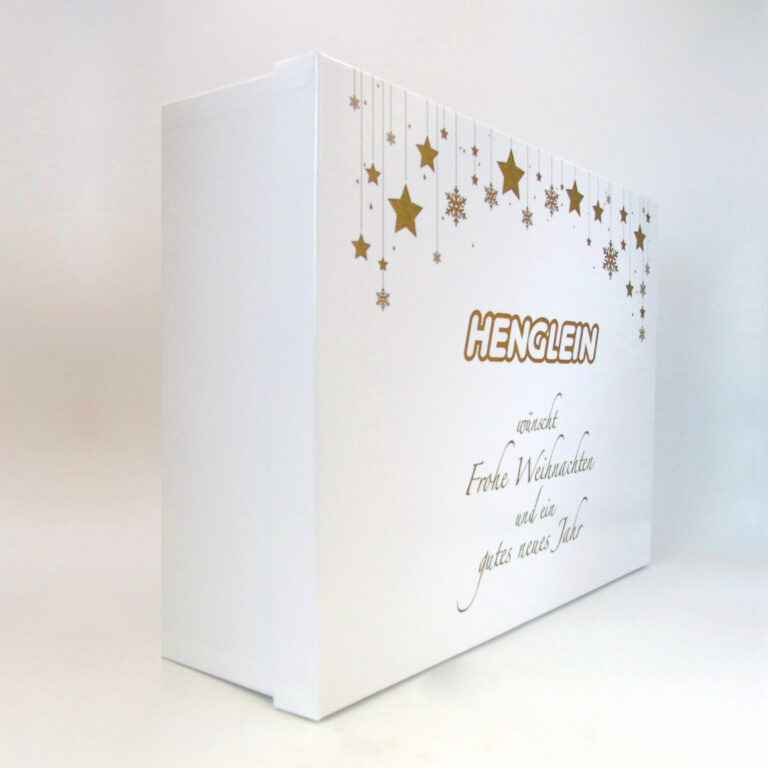

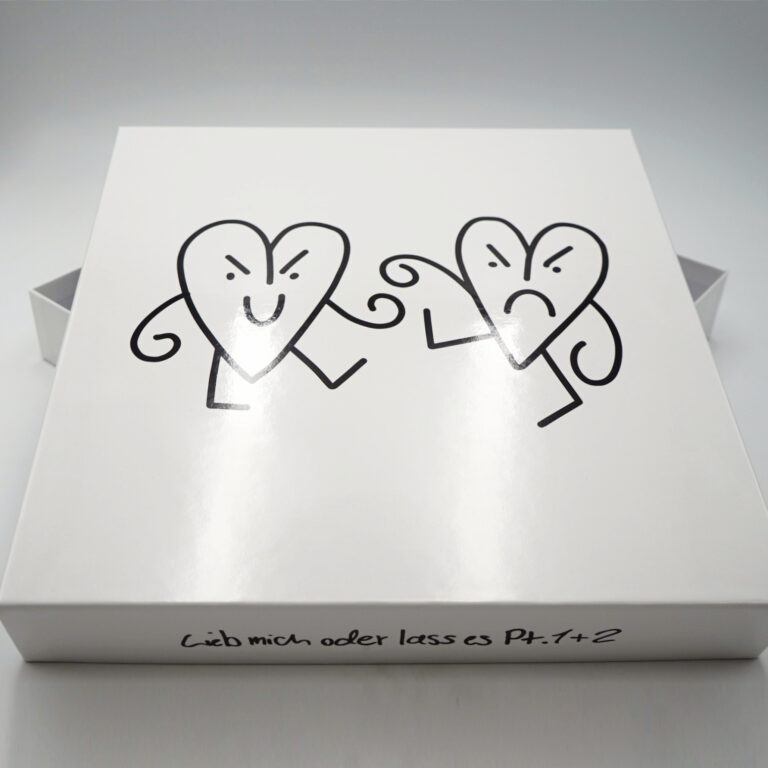

It is possible to print on many different materials using the screen printing process, e.g. paper products, plastics, textiles, ceramics, metal, wood and glass

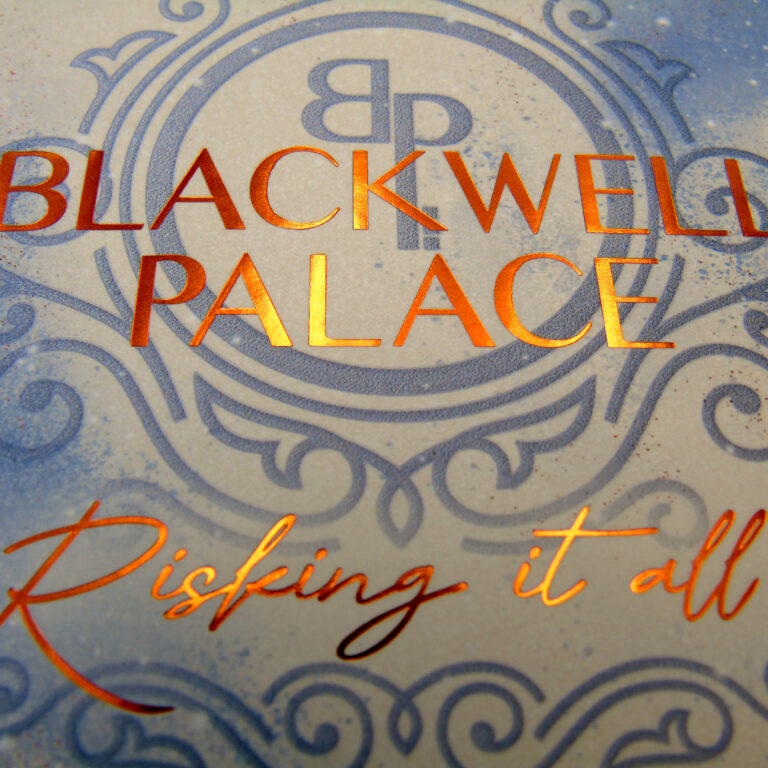

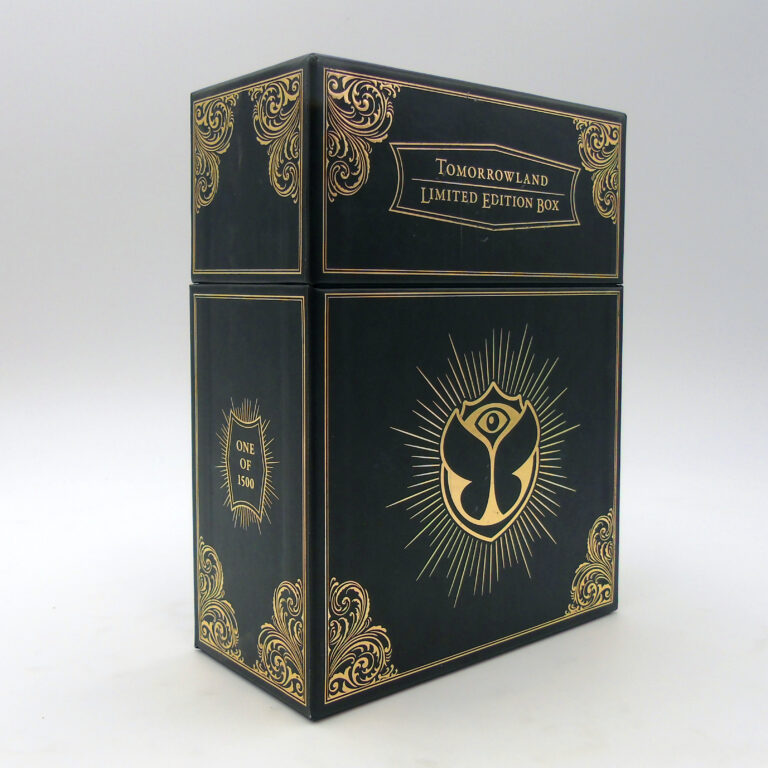

Compared to other printing processes, a relatively thick layer of ink is applied in screen printing. This increases the adhesion, scratch resistance and opacity of the ink. If desired, pigments can be added to the ink to achieve tactile and visual effects: Mica particles, grainy structures.

Screen print opaque white on natural cardboard

In packaging production, screen printing offers a wide range of finishing options. We have been working with our valued Bayreuth supplier for many years and benefit from their experience to turn your packaging into something special.