This is how our fully automatic enrobing systems work.

At Hertel Kartonagen, we rely on state-of-the-art technology to realise first-class packaging solutions. Our six fully automatic coating lines enable the precise and efficient production of reference cardboard boxes such as slip lid boxes, slip cases and hinged lid boxes. These systems are a central part of our production chain and guarantee the highest quality and repeat accuracy.

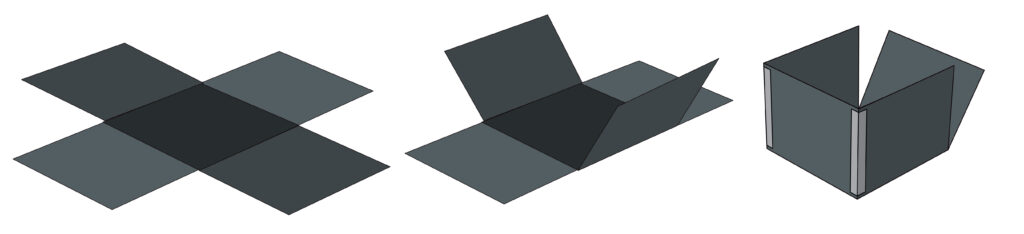

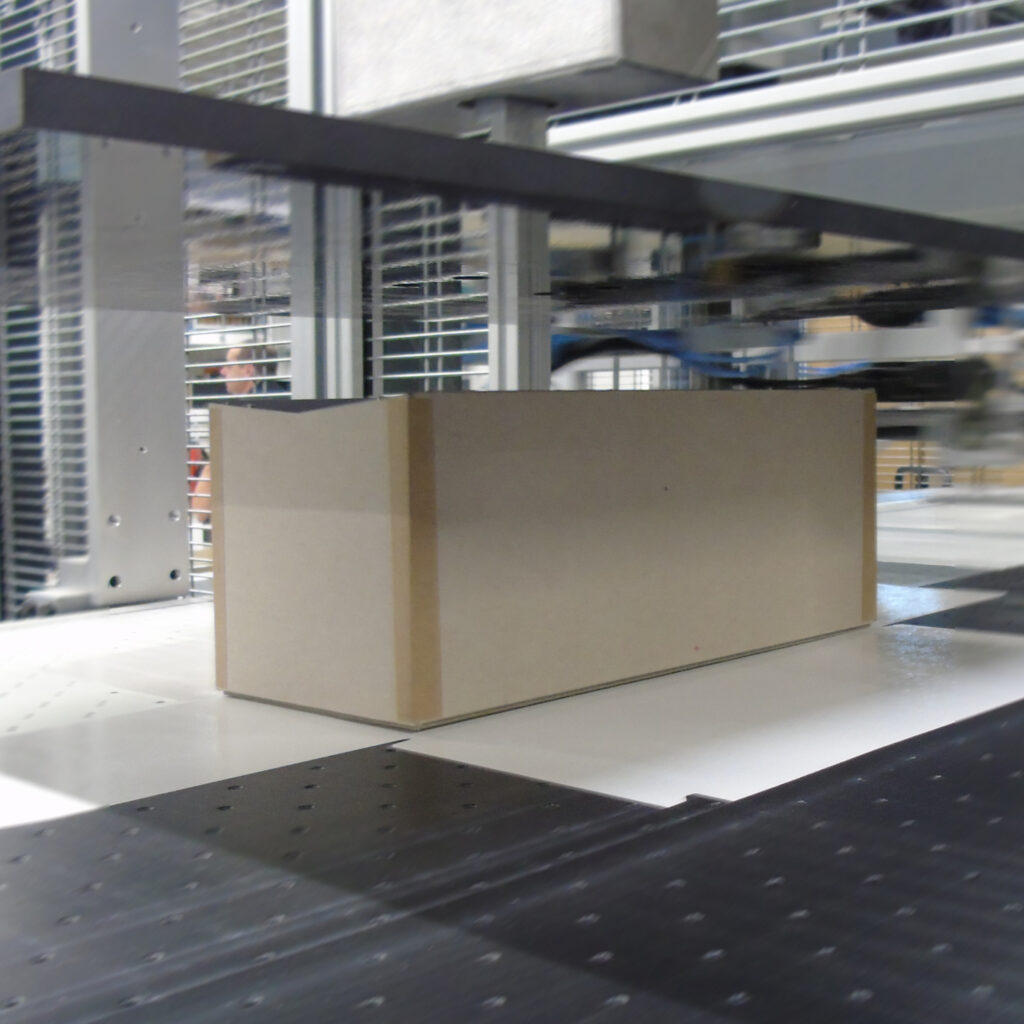

1. erecting and fixing the carton

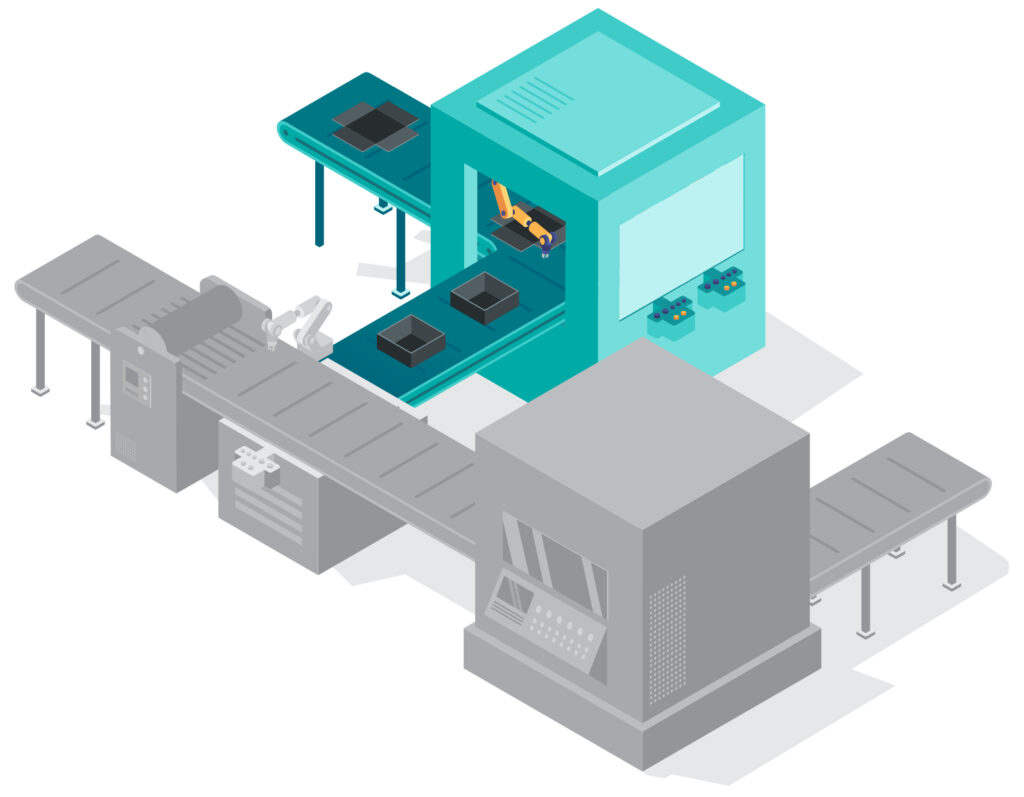

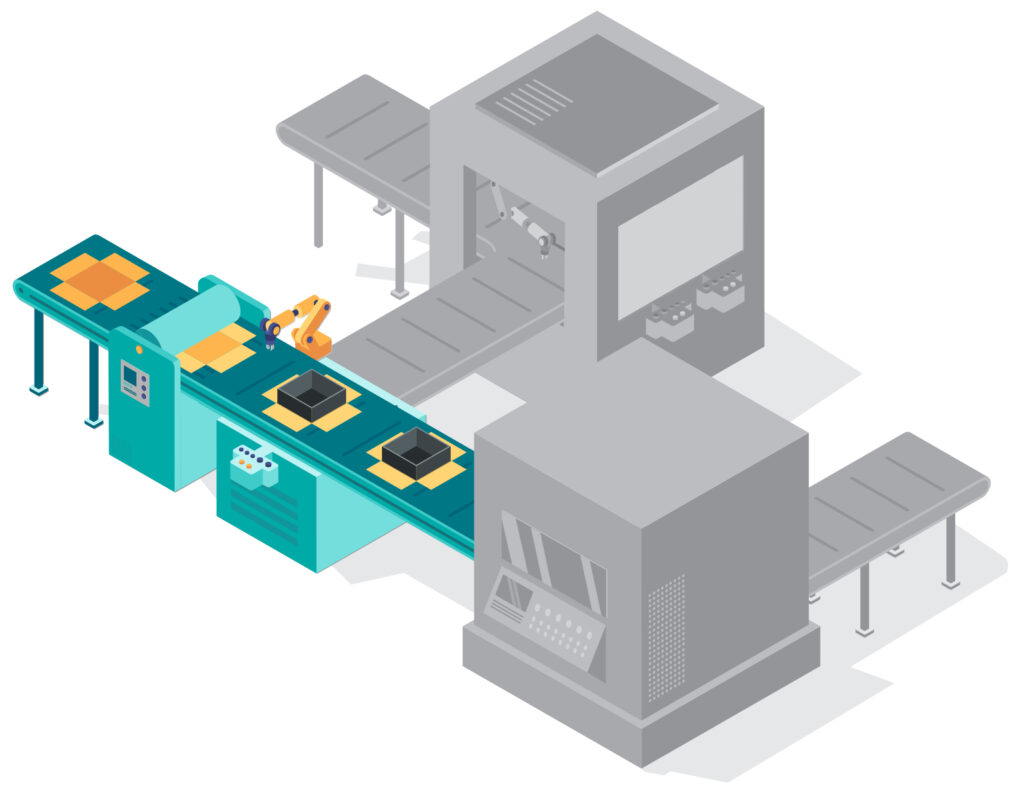

The work step is carried out in the part of the fully automatic coating system that is highlighted in colour.

1. erecting and fixing the carton

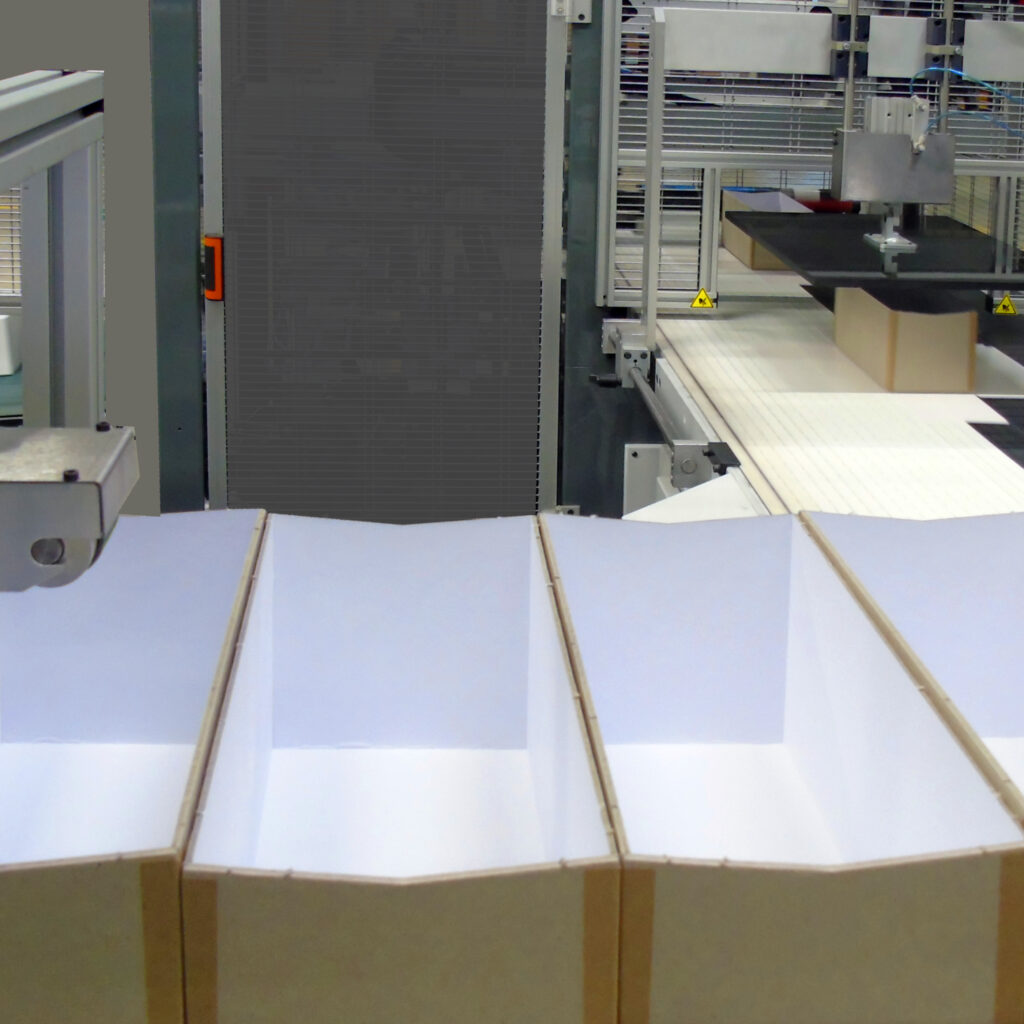

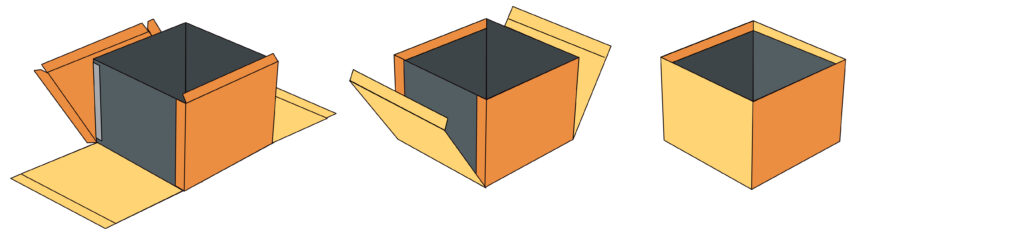

2. application of the coating paper

The work step is carried out in the part of the fully automatic coating system that is highlighted in colour.

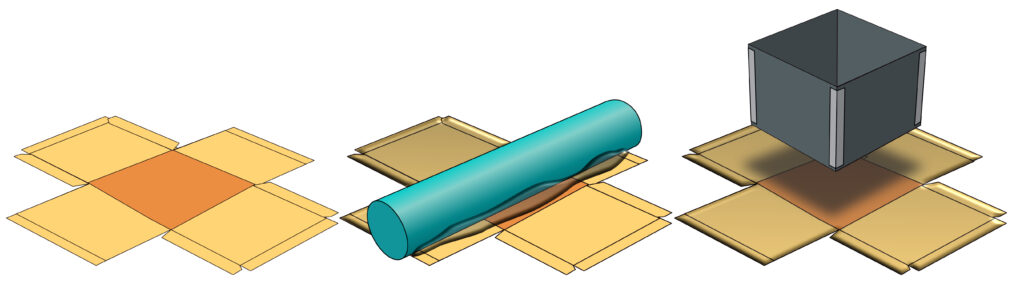

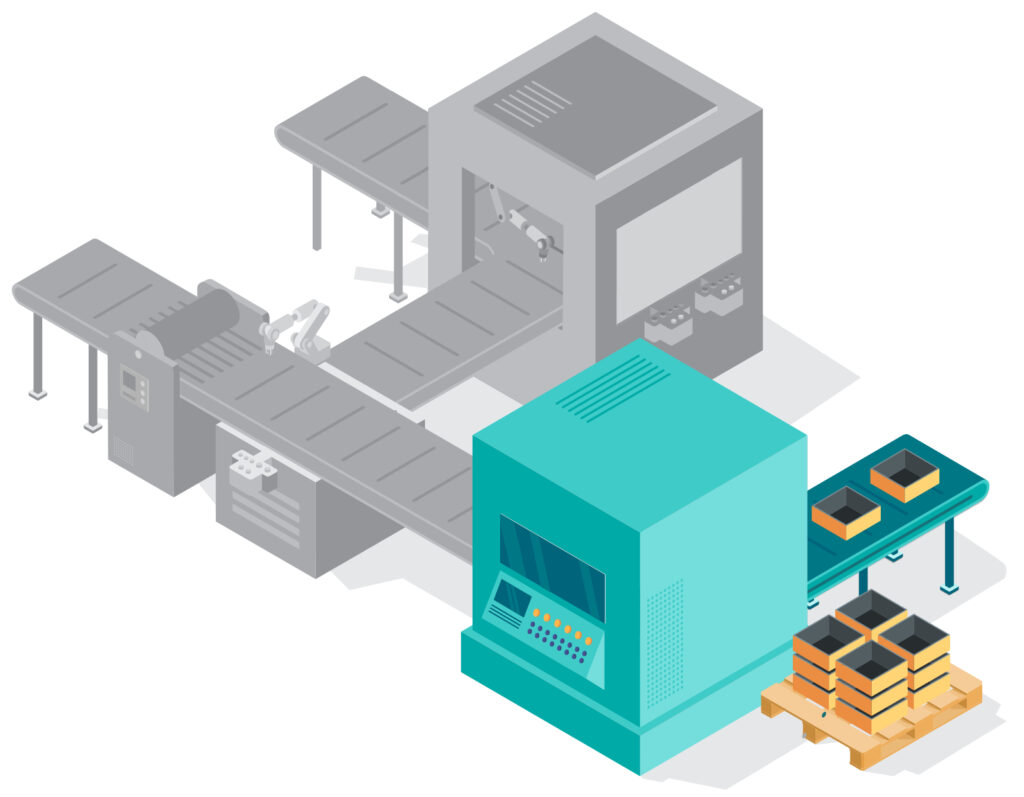

3. coating and edge processing

The work step is carried out in the part of the fully automatic coating system that is highlighted in colour.

You are currently viewing placeholder content from YouTube. To access the actual content, click on the button below. Please note that data will be shared with third parties.

More information