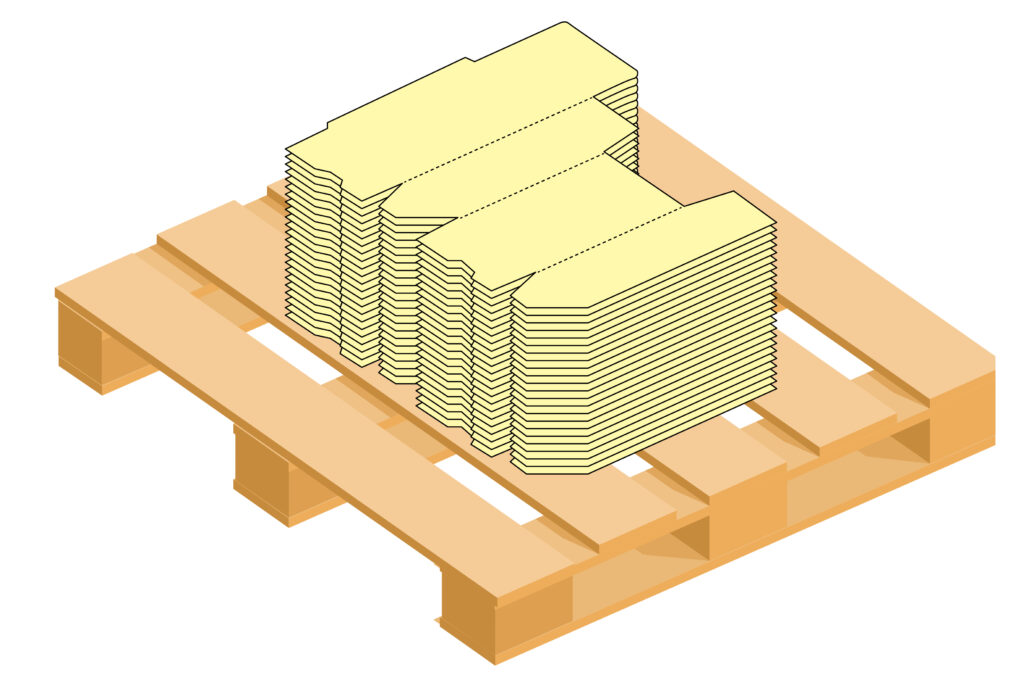

The die-cutting process is a key step in the further processing of cardboard boxes and packaging. Precise shapes are punched out of printed or unprinted sheets using a tool. Typical products are folding boxes, cover papers, packaging inserts or displays.

- 2 fully automatic large-format die-cutting machines for efficient and precise punching

- 2 small-format punching platens for cost-effective small series

How does flatbed die-cutting work?

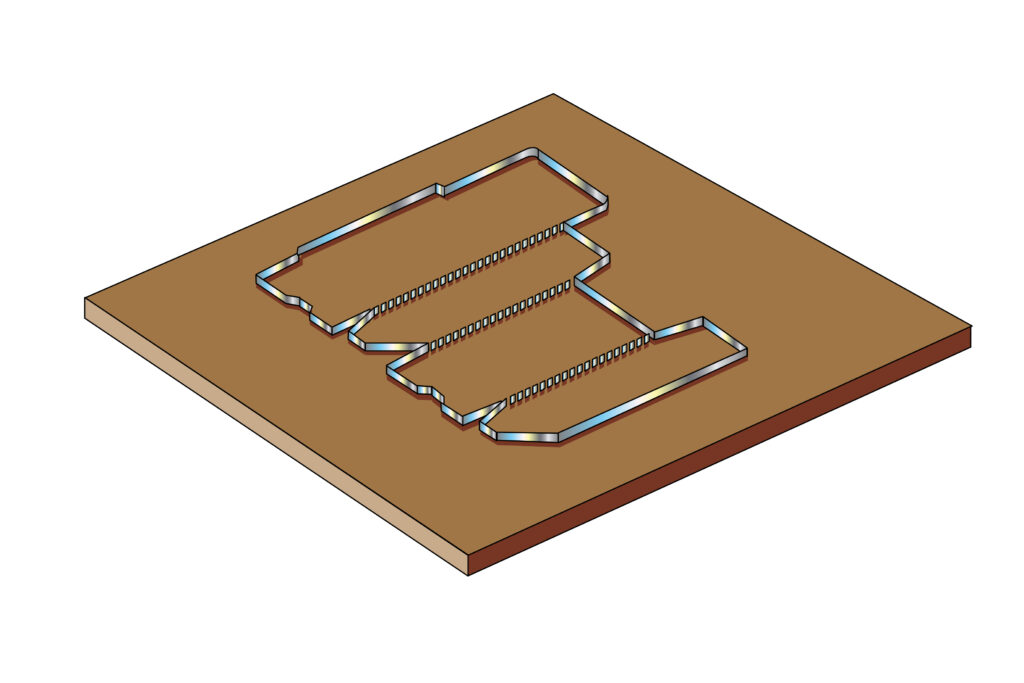

1st cutting die

A suitable cutting die is created for each item. Metal punching, groove and perforation lines are precisely applied to a wooden panel. The cutting die can be reused for follow-up orders.

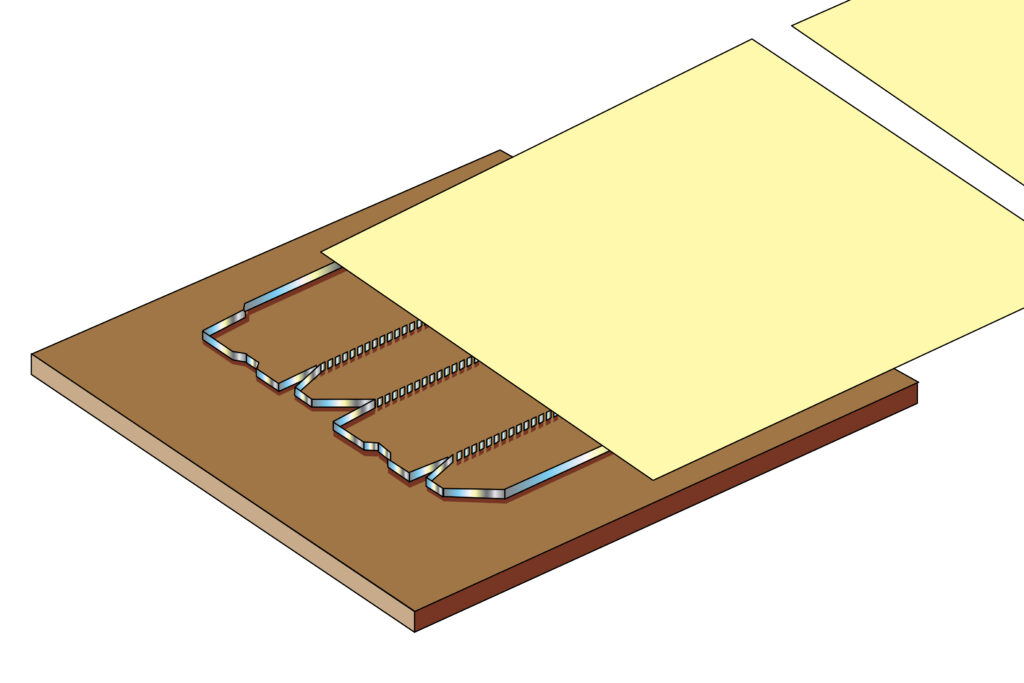

2. exact alignment

An automatic feeder continuously feeds flat sheets of cardboard or corrugated board into the machine at a rate of up to 8,000 sheets per hour. A central register aligns each sheet precisely so that the die-cutting process is accurate to the millimetre - even with printed material.

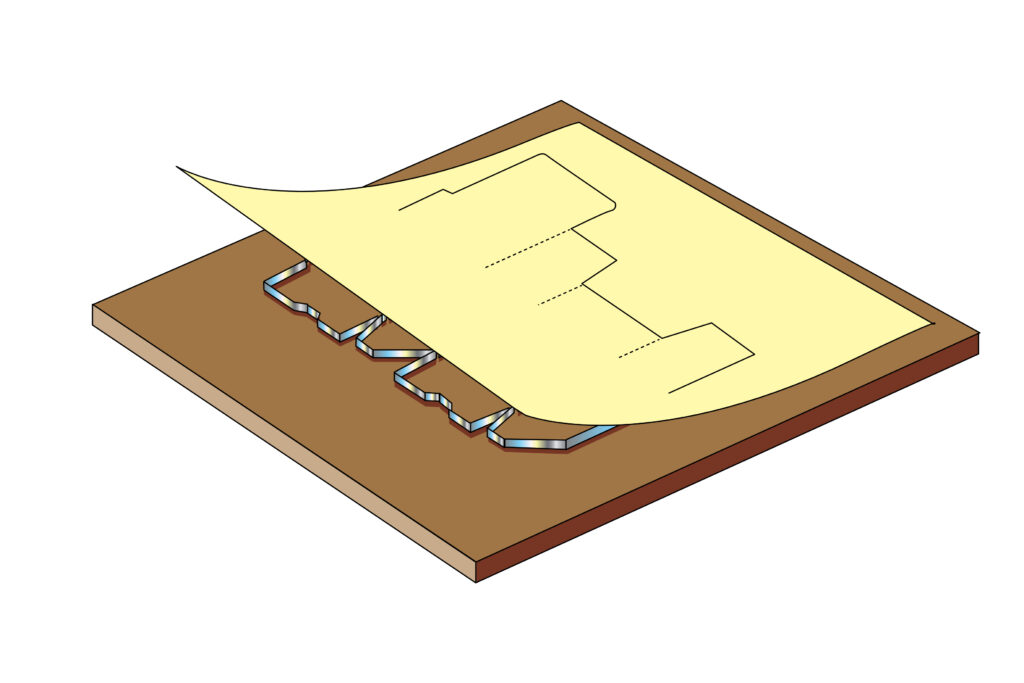

3. punching

At the heart of the machine - the punching station - the material is processed using a customised tool. This creates cuts, creases or perforations, depending on the product requirements.

4. break out

For large runs, the excess parts are automatically broken out; for smaller series, this is done manually in batches after punching.

Advantages of in-house die-cutting

- Better quality control - Direct monitoring of the punching process

- Reusable cutting dies - Economical for follow-up orders

- Fast response times - Ideal for urgent customer orders