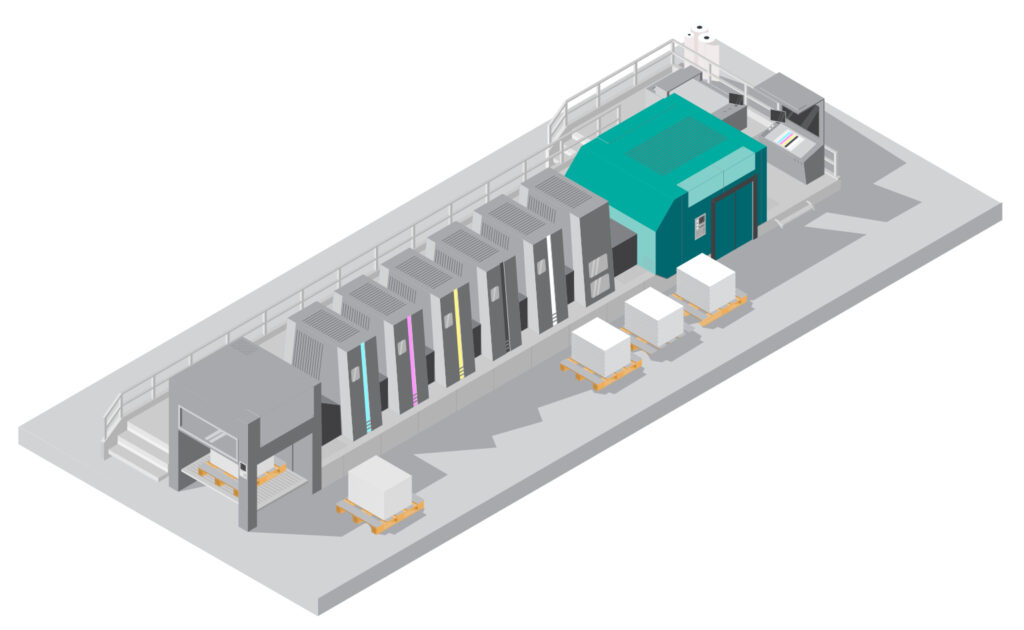

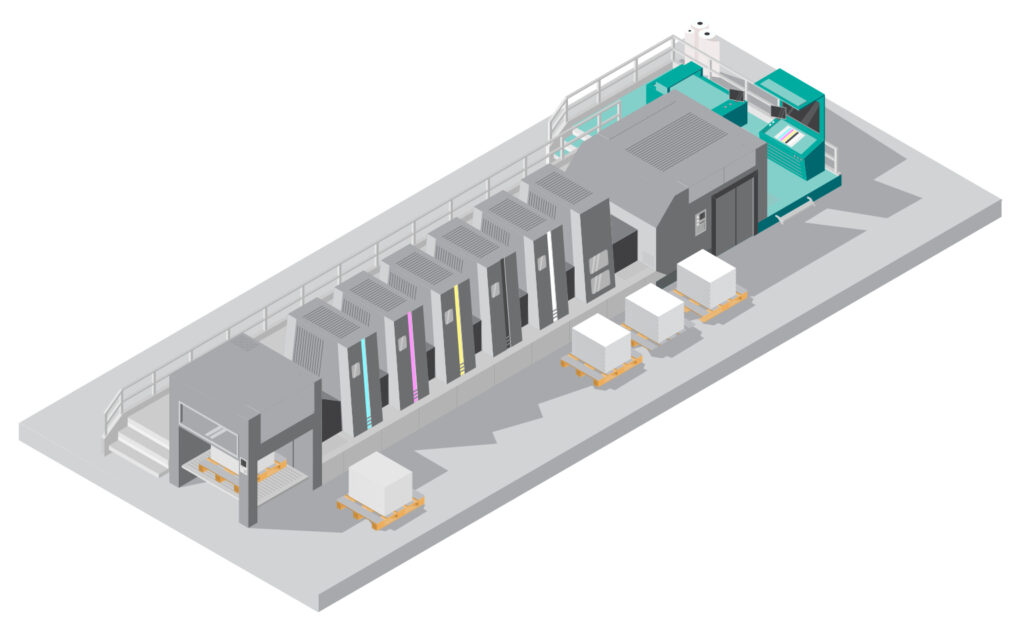

Offset printing is an indirect flat printing process in which the printed image is first transferred onto a blanket and then onto the paper. This technique guarantees the highest print quality and is ideal for medium to large print runs. We produce the required prints in-house on our Heildelberg offset printing machine.

Highest print quality Standardised colour control, no loss of quality with large series

Fast production - up to 18,000 sheets per hour

Environmentally friendly & efficient - Modern technology reduces waste and energy consumption

Advantages of in-house production

- Fast response times - Changes and express printing possible at short notice

- Direct communication - Close coordination with our print team without detours

- Reliable quality control - From data input to the finished product

- Full transparency & planning security - Fixed contact persons, clear processes

- Data security - Sensitive print data remains internal

- Flexibility for special requests - Special colours, finishes or test prints can be realised

- Sustainability - No external transport routes

How does offset printing work?

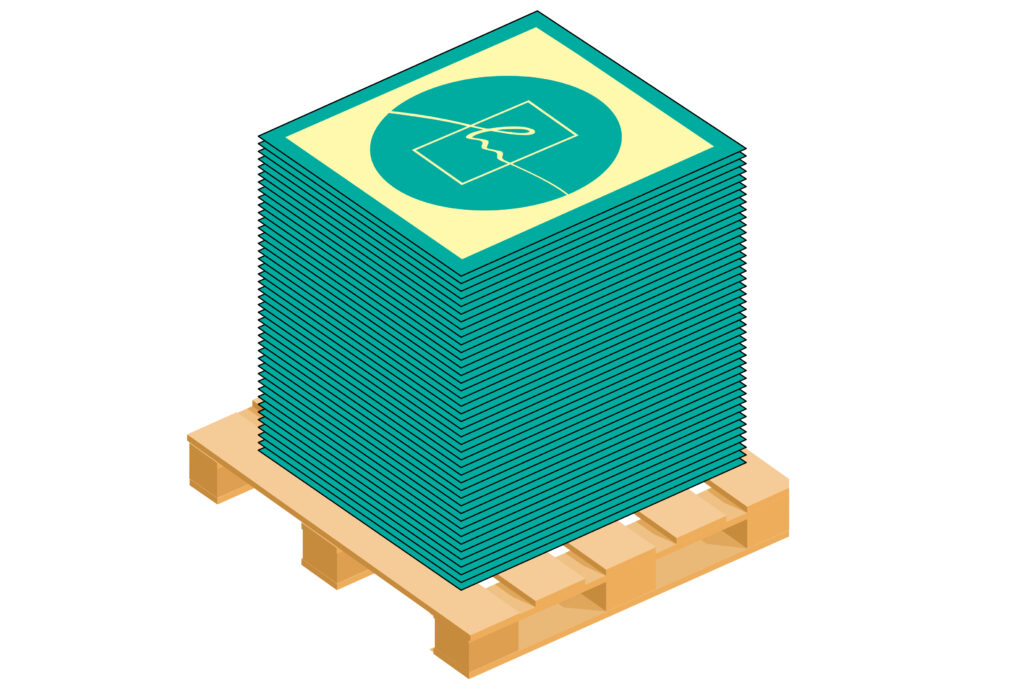

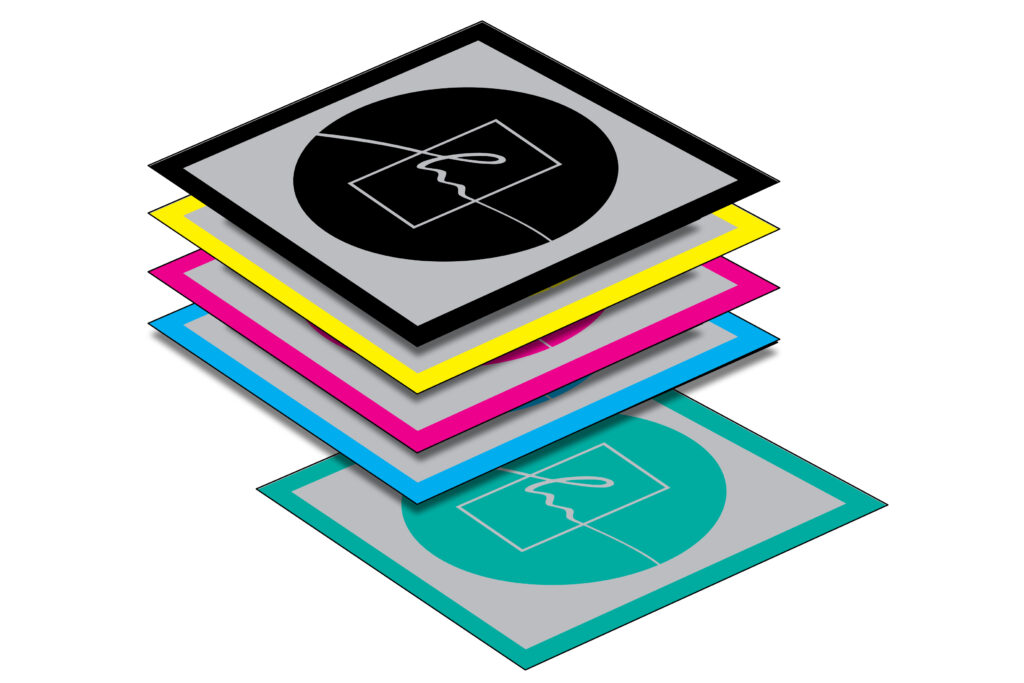

1. prepress

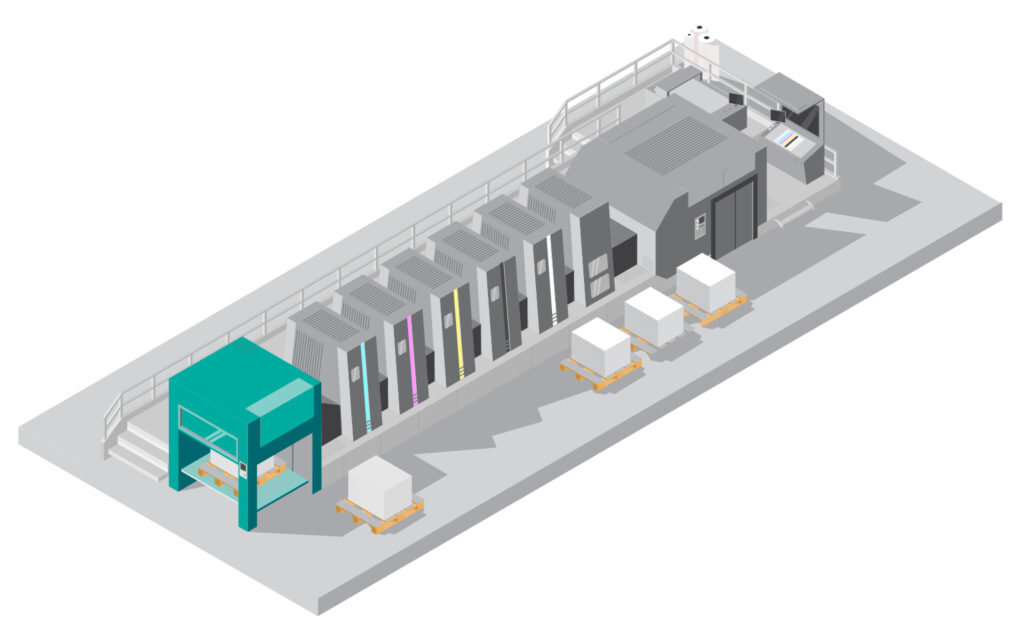

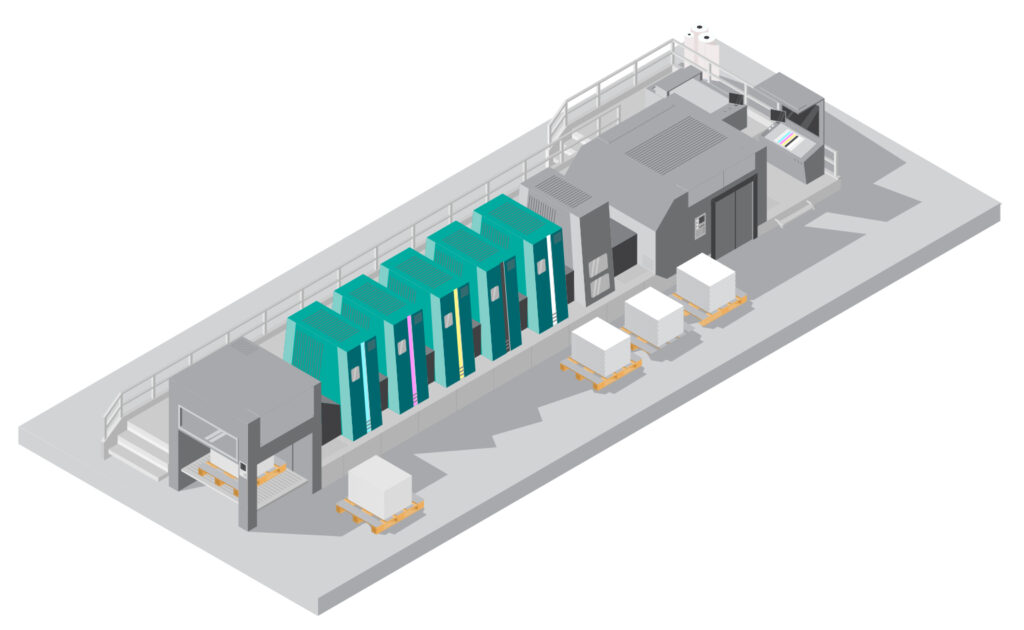

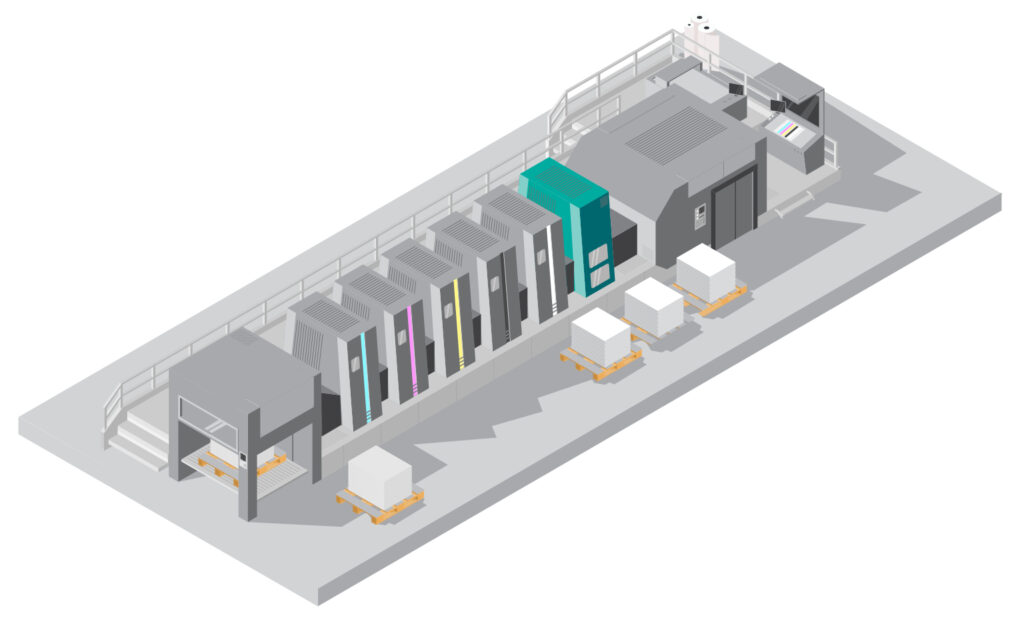

2. disc equipment

The plates are clamped in the printing units of the machine. Each colour has its own printing unit - our machine has 5 inking units that can be assigned individually.

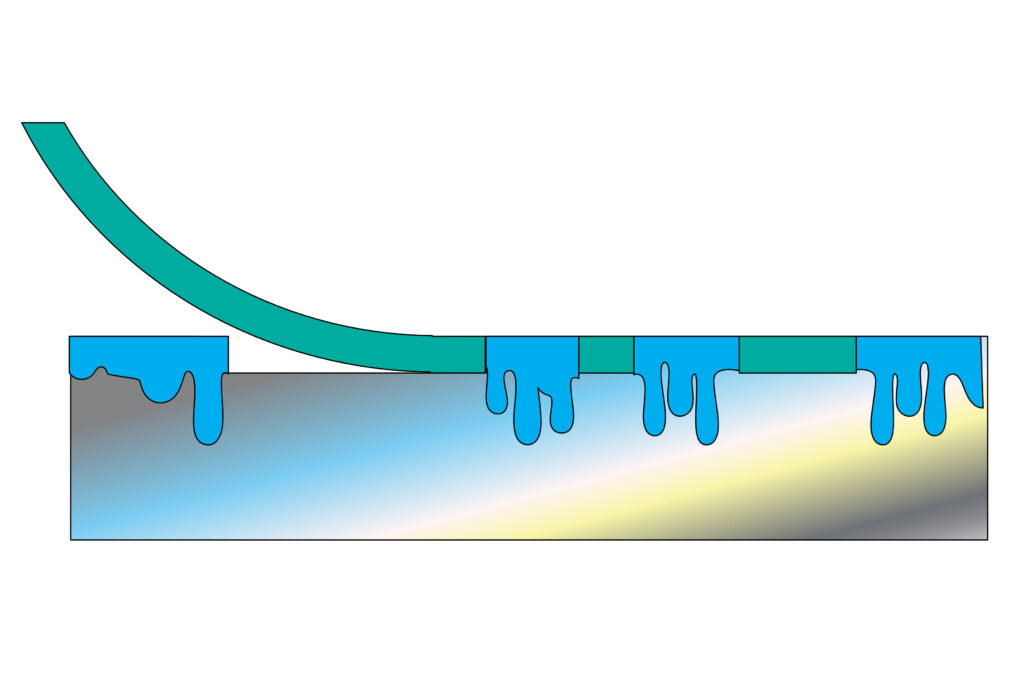

3. colour and dampening solution application

The printing plate is moistened with dampening solution - non-printing areas repel ink. The ink only adheres to the printing areas of the plate.

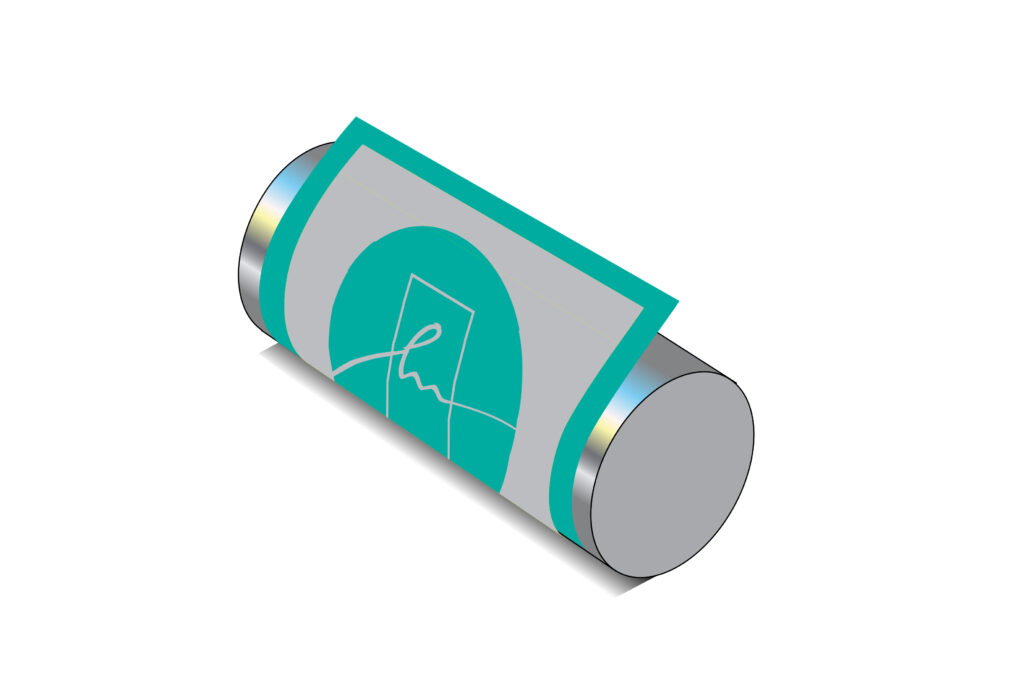

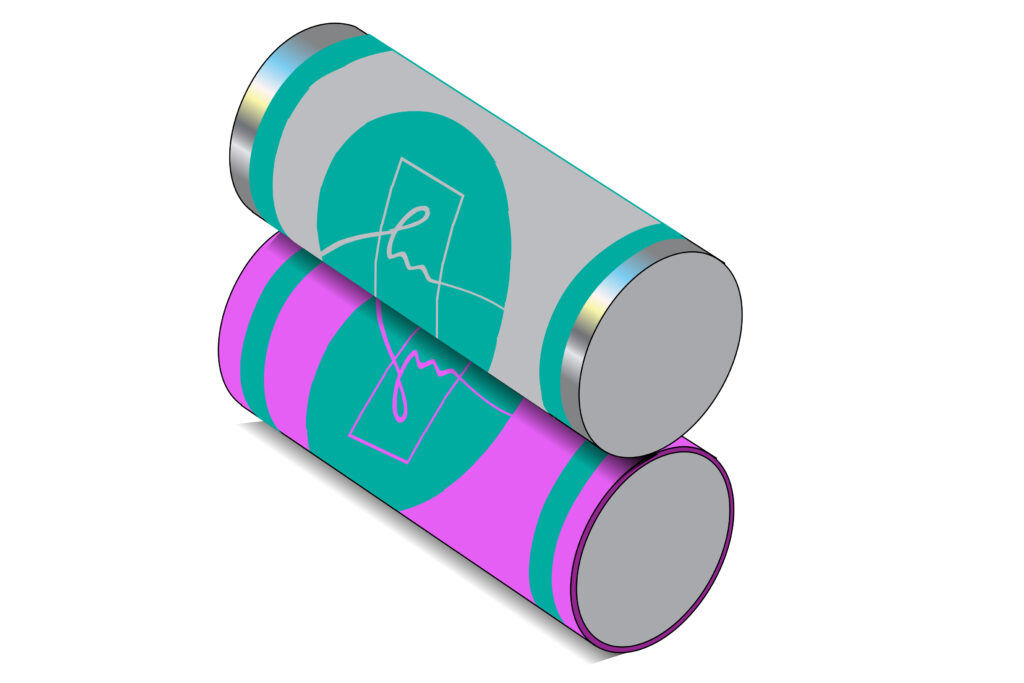

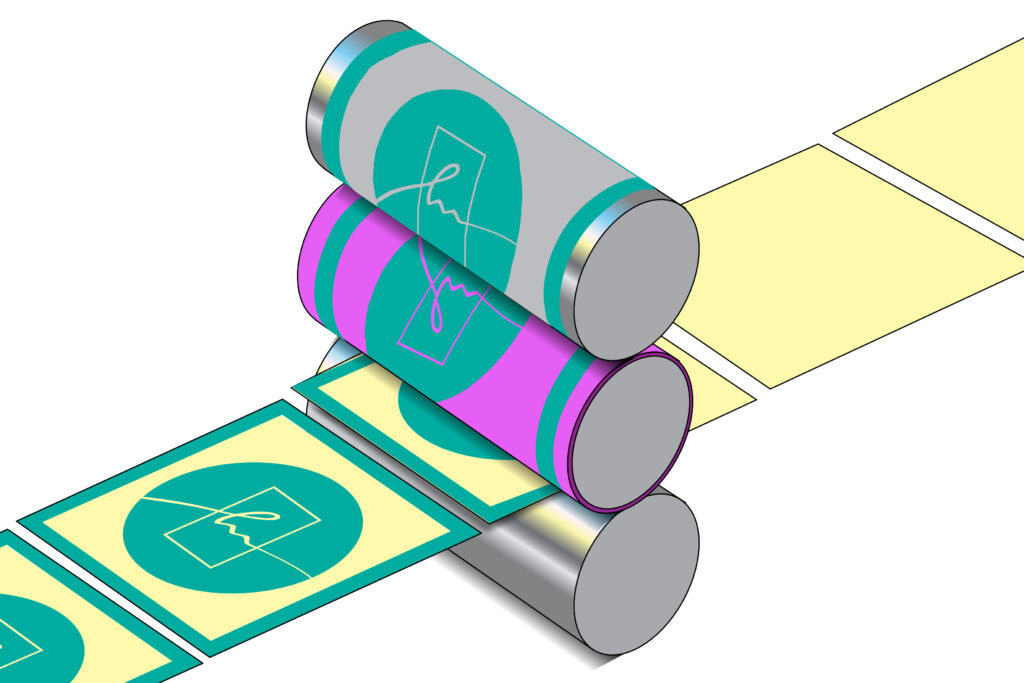

4. blanket cylinder

The printed image is transferred from the plate to a rubber blanket. This flexible material is gentle on the paper and ensures even ink application.

5. paper flow and printing

The paper runs through the machine and picks up the print image from the blanket. Up to 18,000 sheets per hour are possible - with consistently high quality.

6. painting and drying

A protective and/or effect coating is applied in the coating unit. Infrared and UV drying units enable immediate further processing.